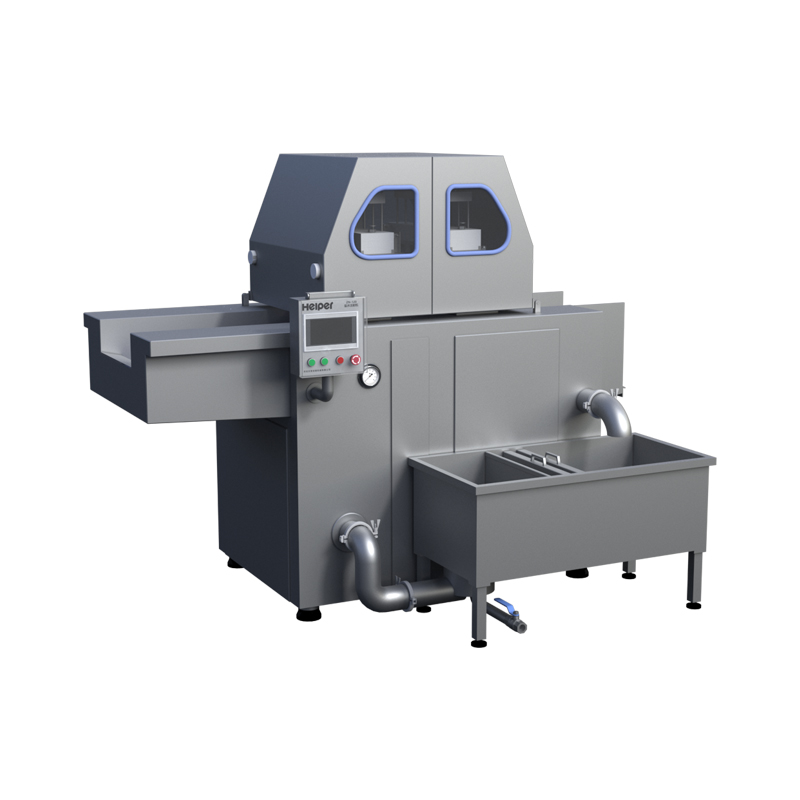

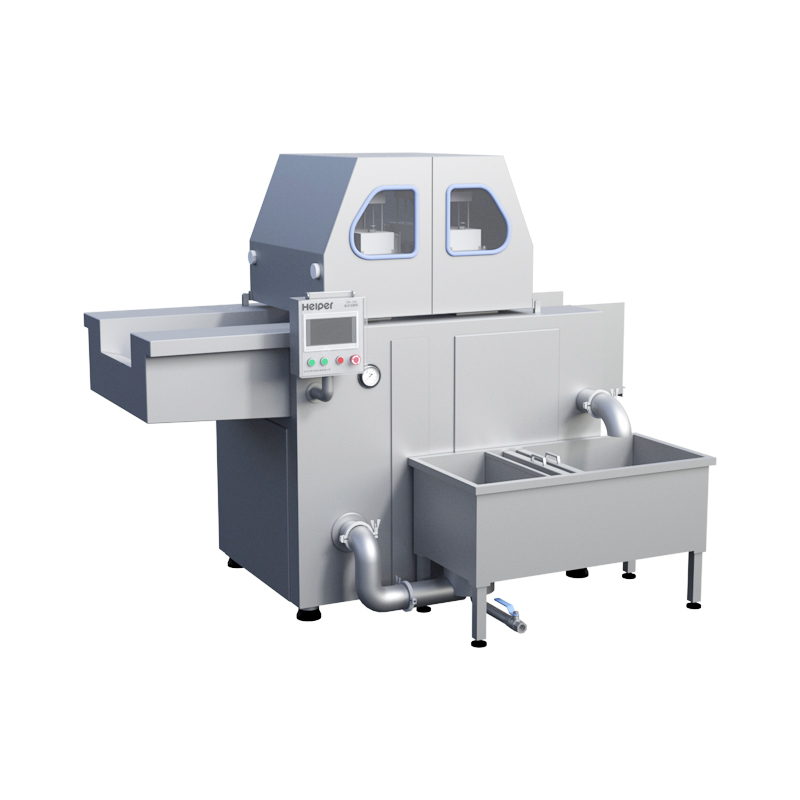

50 Needles Meat Brine Injector Machine

Features and Benefits

- PLC / HMI Control System, easy to set up and operate.

- The main power transmission adopts the internationally advanced variable frequency AC speed control system, with small starting current and good starting characteristics. The number of injections can be infinitely adjusted.

- Equipped with pneumatic needle passing device, which is simple to operate and easy to clean.

- Adopting an advanced servo conveyor belt parallel feeding system, the servo motor is driven accurately and quickly, which can quickly move the material to the designated position with accurate stepping, and the stepping accuracy is as high as 0.1mm, so that the product is injected evenly; at the same time, a quick-detachable handle is designed to facilitate transportation The belt is easy to remove and clean.

- Using German stainless steel injection pump, the injection is fast, the injection rate is high, and it complies with HACCP health standards.

- The water tank adopts an advanced three-stage filtration system and is equipped with a stirring system. The material and water can be evenly blended to make the injection effect better. The salt water injection machine can evenly inject the pickling agent prepared with salt water and auxiliary materials into the meat pieces, shortening the pickling time and greatly improving the taste and yield of meat products.

- Selecting the brine tank configuration makes the brine injection machine more suitable for different process requirements.

a. The brine rotary filter can continuously filter the returning brine to achieve uninterrupted production.

b. The brine tank can be customized with a refrigerated mezzanine.

c. The brine tank can be customized with heating and insulation functions for lipid hot injection.

d. The brine tank can be customized with a slow-speed mixer.

e. The brine injection machine can be equipped with a hydraulic flip-up loading machine to reduce the labor of manual loading.

Technical Parameters

|

Model |

Needles (pcs) |

Capacity (kg/h) |

Injection Speed (times/min) |

Step distance (mm) |

Air Pressure (Mpa) |

Power (kw) |

Weight (kg) |

Dimension (mm) |

|

ZN-236 |

236 |

2000-2500 |

18.75 |

40-60 |

0.04-0.07 |

18.75 |

1680 |

2800*1540*1800 |

|

ZN-120 |

120 |

1200-2500 |

10-32 |

50-100 |

0.04-0.07 |

12.1 |

900 |

2300*1600*1900 |

|

ZN-74 |

74 |

1000-1500 |

15-55 |

15-55 |

0.04-0.07 |

4.18 |

680 |

2200*680*1900 |

|

ZN-50 |

50 |

600-1200 |

15-55 t |

15-55 |

0.04-0.07 |

3.53 |

500 |

2100*600*1716 |