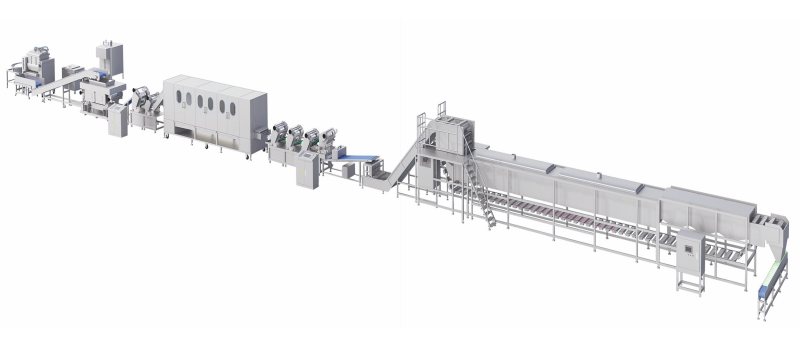

The HELPER fully automatic noodle production line adopts an intelligent integrated data operating system, and the data is controllable from dough mixing to rolling and cutting. The entire production line only requires two people to operate, and can complete 600-1200kg in the market. Therefore, it is particularly important to maintain this highly intelligent equipment and extend the service life of the equipment.

First of all, The noodle machine can be idle for about 10 minutes before running. Listen to whether the machine has abnormal sounds. If so, it can be started after troubleshooting. In winter, when the temperature is low, the machine can be preheated first.

Secondly, do not mix hard objects into the flour when producing noodles to avoid damaging the machine. In order to ensure the wear of the product during the production process, lubricants should be added to the parts regularly to ensure that the parts can be produced in good condition. Therefore, the staff should regularly check the condition of each part and replenish lubricating oil in time to ensure smooth production.

After shutting down, clean the machine and remove the remaining dough for next use

When the fresh noodle production line has been used for a period of time, or because of long-term wear and carelessness, some noise or abnormal noise may occur. Here are ways to solve these noises:

1. When the motor bearing is found to be damaged, a few drops of lubricating oil should be injected between the shaft and the bearing, and then listen to see if the noise has been greatly reduced. If not, it indicates that the bearing is severely worn and needs to be replaced.

2. Check whether the reducer of the raw noodle production line is damaged. Open the gearbox cover and observe each gear. If damaged, replace the damaged gear.

Check whether the grease in the reducer is too little. If too small, increase the grease of the gearbox appropriately and check whether the commutator is severely worn. If damaged, replace and check whether the motor rotor is open circuit. Open the brush and measure the resistance between the two commutators. When the resistance between the two sets of commutators is large, it indicates that there is an obvious phenomenon in the winding here. Generally speaking, replace the rotor because it is more troublesome to rewind the rotor.

Post time: Jul-12-2025